What is Oxygen Cleaning?

Leave a CommentOxygen cleaning is a critical process in industries where the purity of oxygen contact surfaces is paramount. This specialized cleaning procedure is a process to help remove contaminants like oil, grease, organic or inorganic from vats, tanks, and other containers

We do oxidation services by purifying tanks, vats, equipment and other industrial containers from the dangers of their product mixing with the residue chemicals, by cleaning them with either liquid or gaseous oxygen. Continue reading to learn more about this essential process

Understanding Oxygen Cleaning

Oxygen cleaning refers to the process of purifying equipment designed for operation with liquid or gaseous oxygen. In oxygen-enriched environments, contaminants represent significant hazards. Employed in industrial contexts, this cleaning method is critical for removing flammable contaminants and mitigating the risk of fires or explosions.

The fundamental difference between oxygen cleaning and standard cleaning procedures lies in the level of cleanliness required and the method of removing contaminants. Standard cleaning may involve removing visible dirt, grime, and oils from surfaces, often focusing on aesthetic cleanliness rather than eliminating potential chemical reactants.

In contrast, oxygen cleaning goes beyond surface cleanliness to remove microscopic particles and organic or inorganic substances that could ignite or react when exposed to high oxygen concentrations. This requires specialized solvents, equipment, and techniques to achieve a level of purity where the equipment can be safely used in oxygen-rich environments.

Oxygen Cleaning Procedure

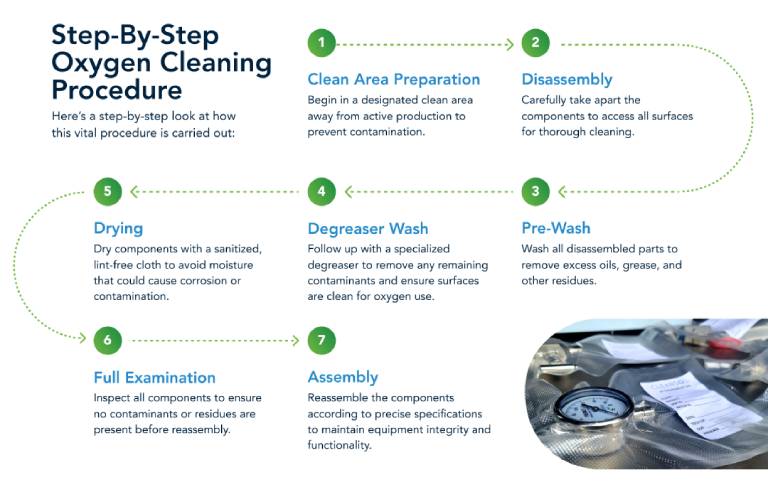

The oxygen cleaning procedure entails several critical steps to completely remove contaminants and achieve the necessary purity level for safe operation in oxygen-enriched environments. Here’s a step-by-step look at how this vital procedure is carried out:

- Clean Area Preparation: The procedure begins in a designated clean area of the facility, far from active production units. This separation minimizes the risk of contamination during the cleaning process.

- Disassembly: The components requiring cleaning are carefully disassembled. This step allows thorough access to all surfaces, ensuring a comprehensive cleaning process.

- Pre-Wash: All disassembled components undergo a pre-wash stage. This initial wash is crucial for removing excess oils, grease cuttings, and other materials that may have accumulated during regular operation.

- Degreaser Wash: After the pre-wash, the components undergo a final wash with a specialized degreaser. This removes any remaining contaminants, leaving the surfaces clean and ready for oxygen service.

- Drying: Following the degreaser wash, components are dried meticulously using a sanitized, lint-free cloth. This drying stage is essential to eliminate any moisture that could lead to corrosion or contamination.

- Full Examination: A technician inspects all components before assembly. This thorough examination ensures no contaminants or residues are overlooked, guaranteeing the equipment’s readiness for oxygen use.

- Assembly: Once the components are thoroughly dried and inspected, they are carefully reassembled according to precise specifications. This assembly process is critical for maintaining the integrity and functionality of the equipment post-cleaning.

Following these meticulous steps, the oxygen cleaning procedure achieves the cleanliness and purity necessary for safe and efficient operation in oxygen-enriched environments. This systematic approach ensures maximum efficiency, safety, and compliance with standards across various industries.

Secure Your Operations with Expert Oxygen Cleaning Services

Understanding what oxygen cleaning is and the meticulous cleaning procedure highlights its critical role in ensuring the safety and efficiency of equipment in oxygen-enriched environments. Cleansol LLC provides professional oxygen cleaning services that adhere to ISO standards, ensuring that your equipment meets the highest safety and quality benchmarks.

With a 24-hour turnaround service, we are committed to minimizing downtime and maintaining the optimal performance of your systems. Contact us today to learn more about how our expert services can support your operational needs.